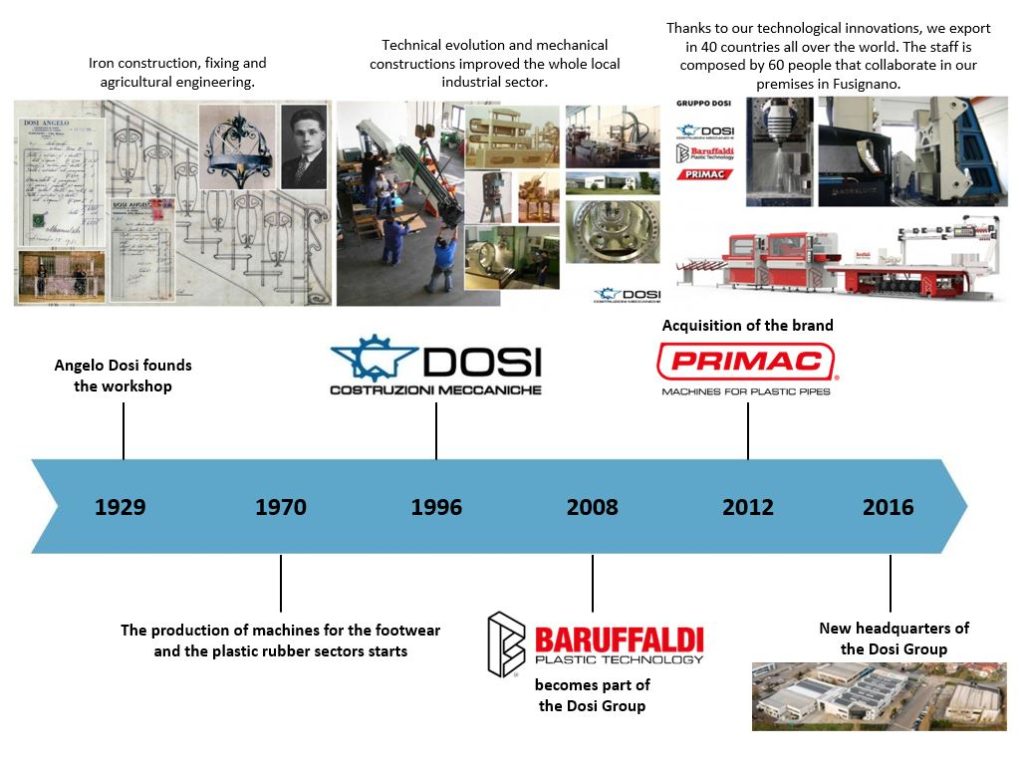

The Dosi Srl company was founded in 1929 by Mr. Angelo Dosi as a workshop. The strong mechanical tradition allows us to create complete cycles, from prototype to assembly, assembling and testing finished units and machines.

Our customers are leaders in their sectors, and operate mainly in the markets of precision mechanical systems, automatic machines, packaging, plastic processing machines, earthmoving and road moving machines.

Currently the company operates on a covered area of 5000 square meters, according to the procedures provided for by the ISO 9000 quality certification to ensure the satisfaction of its customers.

Always sensitive to environmental issues, Dosi is a “0 emissions” company as the photovoltaic systems installed in our factories produce the internal electricity needs. The property acquired at the end of 2008 the company Baruffaldi Plastic Technology, which operates internationally in the production of machines for the extrusion and processing of plastic profiles; it also completed the range of automatic machines by integrating the Primac brand into the group, dedicated to systems for smooth and corrugated pipes.

Thanks to the hospitality of the Dosi family, the Romagna Air Finders Museum was able to find its perfect location in Fusignano, giving new life to what once was the workshop of Angelo Dosi, grandfather and predecessor of the current CEO of Dosi Srl, Mr. Alberto Dosi. Inside the historic workshop, three large rooms have been recreated, exhibiting the finds accompanied by audio and video supports.

Mr. Dosi is really proud of this initiative and said “There is no better result, than to be able to see a place of my childhood, loved by me as much as the man who created it, my grandfather, who gave me the passion for this work and the company values that have always guided me “.

Dosi Srl is the holding company of a network of entreprises who work in sinergy to offer to their customers a high quality service.