The Dosi Group, which has always been sensitive to environmental issues and winner of the Excelsa 2021 award for sustainability, decided to undertake a path to be able to measure and monitor the sustainable development of its companies. Starting from 2021, in collaboration with the University of Bologna and NIER Engineering, it therefore began this process aimed at quantifying its sustainability through ViVACE.

ViVACE (Visualization of Value on Circular Economy) is a tool, created by the University of Bologna, for visualizing the circular economy, to quantify and manage the current level of circularity of companies and to allow the identification of projects and sustainable initiatives. The aim is to provide a method for assessing the environmental, social and economic performance of companies through an aggregate score of indicators. Right now, the environmental model has been applied within the Dosi Group.

The project was articulated through an initial Gap Analysis, aimed at identifying the strengths and weaknesses of the companies, to investigate the most relevant processes. The analysis highlighted the strengths of the companies, that is: i) continuous investments in latest generation plants and machinery for an improvement of work environment and product; ii) digitization of production through the application of Industry 4.0 to existing machinery; iii) high level customer service thanks to the good practice of ISO 9001, the collaboration with strategic suppliers and the high flexibility of the production process; iv) use of renewable energy from the 3 modules of photovoltaic panels, which allow the reduction of energy taken from the grid. From the Gap Analysis it was possible to identify the first two points to be improved: the proactive management of the circularity of the Group’s companies and the identification of some strategic interventions on production processes, that will be a source of improvement.

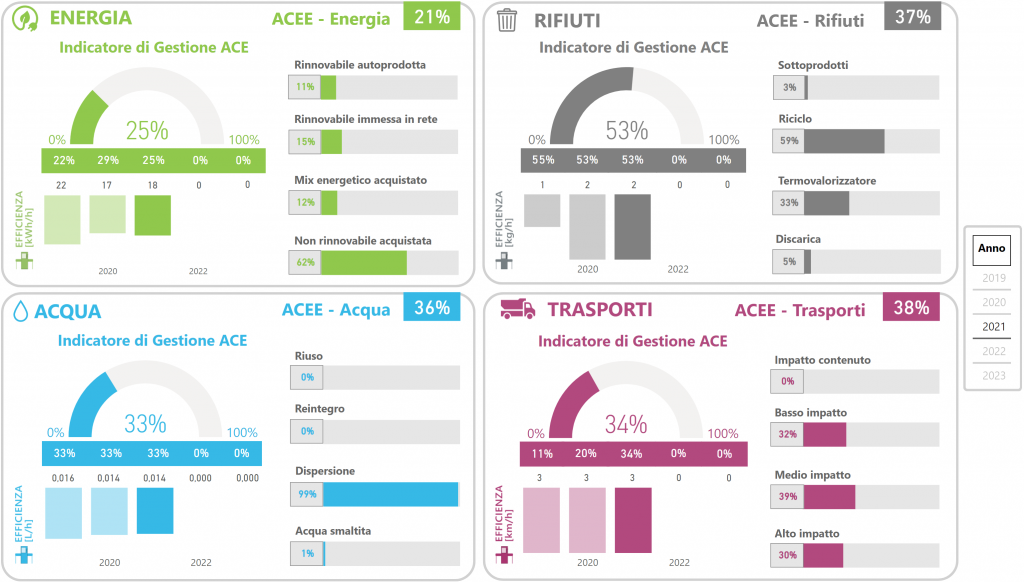

Subsequently, the collection and processing of the most significant data of the last 3 years was set up with the ViVACE model. Dosi found a partial reduction in CO2eq emissions against a decrease of about 3% in energy consumption compared to 2019, while increasing its turnover. This reduction is mainly associated with the drop in energy consumption, which compared to 2019 was reduced by 15% with a decrease in emissions equal to 24%. This reduction was possible thanks to measures related to energy efficiency, i.e., the replacement of some air conditioning systems and older machinery with new generation ones equipped with Industry 4.0. The group has also installed air cooling systems for the summer period with water-based exchangers with reduced energy consumption, to improve the working environment of its employees, without increasing electricity consumption.

The companies generate renewable energy thanks to the use of photovoltaic panels; the self-consumption of the energy produced is more than 40%, while the remaining is fed back into the network. Thanks to renewables, companies are able to cover 30% of their electricity needs and 15% of total energy needs. In addition to the energy aspects, it is implementing an update the company vehicle fleet, with low energy impact vehicles: this activity, while keeping the kilometers traveled by the vehicles constant, reduced emissions by 25% compared to 2019.

Despite the impact of Covid, Dosi has increased its production capacity in the last three years. This led, consequently, to an increase of about 40% of the waste produced, of which however 95% is sent to recycling and energy recovery activities. The topic is of great interest and in the coming months more attention will be paid to waste management, through prevention and reduction paths. Valuation and reuse models have been identified within the group’s activities and possible synergies with external companies.

ViVACE also showed a sharp drop in CO2 emissions deriving from the trips of the Baruffaldi technicians to support and visit the customer, in particular those related to air traffic. In fact, the number of flights has drastically dropped, due to an estimated 86% reduction in CO2eq emissions compared to 2019, not only due to Covid, but above all thanks to the “Smart Industry” platform which has allowed interventions and plant start-ups. remotely. This platform, which will be implemented in all the new machines, will not only reduce the number of trips and consequently the CO2 emitted, but will also be able to monitor the consumption and waste of the Baruffaldi machines, thus making the machines more efficient and sustainable. In this way it will be possible to integrate the circular economy within the Industry 4.0 paradigm.

Following the results obtained, the Group has identified the main objectives to be achieved in the following two years:

Thanks to the ViVACE model, it is possible to have indicators for the decision making phase, but also to continuously monitor the various parameters, thus making a proactive reaction possible. With ViVACE, we have not only a photo at the end of the year of what has been the trend of our actions from the point of view of sustainability, but also a continuous video that allows us to check the trends of the various indicators and to react promptly.

The goal is to manage the productivity of companies from a circular point of view, through best practices that make it possible to improve the energy efficiency of the departments and, consequently, to reduce CO2 emissions throughout the production cycle. The final goal is to optimize the Baruffaldi machines to the maximum in a circular economy perspective, not only by reducing the components used or using recycled raw materials, but also by decreasing the waste that these machines produce, lowering their energy consumption and designing them with a attention to the end of life (design for end of life).

Dosi Srl is the holding company of a network of entreprises who work in sinergy to offer to their customers a high quality service.